Grinding mix welding is a strong-state welding process that utilizes a non-consumable device to join two metal parts. Liquid cold plate heat sink with erosion mix welding is reasonable for many utilizations. The grinding mix welding process is utilized to join the metal parts of the virus plate together. The applications are below:

Automotive

Fluid cooling with grinding mix welded cold plates is fundamental for electric vehicles, as they require effective intensity dissemination to guarantee solid and stable activity.

Medical equipment

Fluid cooling with rubbing mix welded cold plates is normally utilized in clinical gear, for example, X-ray machines, to keep up with stable working temperatures and guarantee precise execution.

Aerospace

Fluid cooling with contact mix welded cold plates is utilized in airplanes and shuttles to maintain stable working temperatures and guarantee solid and exact execution.

High-Performance Computing

Fluid cooling with rubbing mix welded cold plates is essential for superior execution processing applications, for example, server farms, supercomputers, and gaming laptops. The subsequent virus plate guarantees proficient intensity dissemination, guaranteeing solid and stable activity.

Kingka Liquid Cold Plates with Friction Stir Welding

Kingka offers various fluid virus plates with rubbing mix welding to address the issues of various applications. Their virus plates include excellent materials, high-level assembling strategies, and adaptable plans. Kingka cold plates incorporate existing cooling frameworks and deal with predominant warm execution. Fluid virus plates with contact mix welding are a top-notch answer for productive intensity scattering in superior execution electronic parts. The grating mix welding process delivers top-notch welds with further developed exhaustion properties and decreased contortion, bringing about a virus plate that is solid, stable, and exact. Fluid cooling with grating mix welded cold plates is reasonable for many uses.

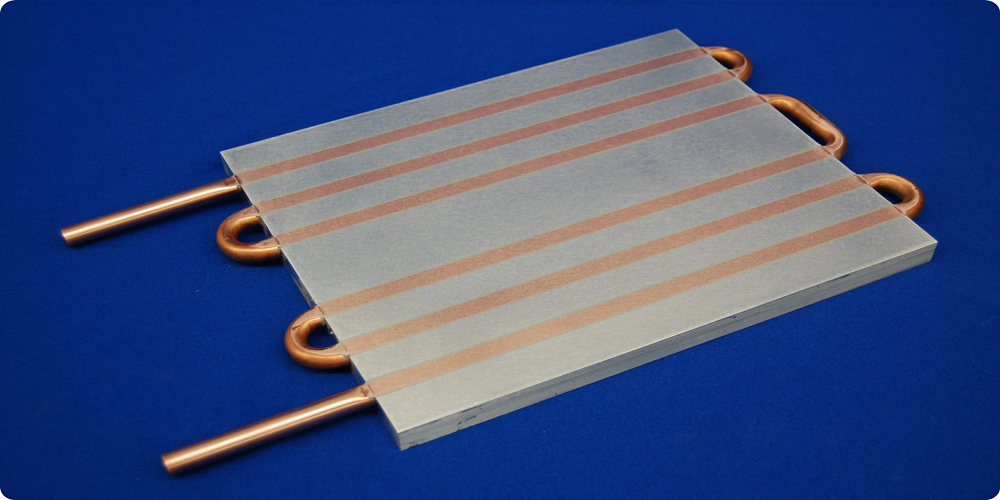

What is liquid cold with copper?

Fluid virus plates with copper are heat exchangers that utilize fluid coolant to move heat away from electronic parts. The cold copper plate is a metal plate machined to incorporate inner channels for the progression of coolant. The coolant retains heat from the parts and afterward courses through the channels, where an outer intensity sink or a fluid cooling framework cools it. Copper has great warm conductivity, implying it can move heat rapidly and productively. Copper has the most elevated warm conductivity of every normal metal, making it an optimal material for fluid virus plates. Copper is likewise exceptionally sturdy, consumption safe, and simple to machine, which makes it a financially savvy material for fluid virus plates.

Advantages of the liquid cold plate with copper

Copper is exceptionally tough and erosion safe, which makes it an optimal material for fluid virus plates. Copper cold plates are impervious to mileage, making them a dependable and enduring arrangement. Copper is a recyclable material that can be reused in new items, which goes with it a harmless to the ecosystem decision for fluid virus plates. Copper has great warm conductivity, which empowers productive intensity to move from the parts to the coolant, resulting in lower working temperatures and further developed framework execution. Copper is a savvy material for fluid virus plates, as it is not difficult to machine and broadly accessible. This makes cold copper plates a reasonable answer for many uses.