Sheet metal bending is essential in this current economy. Thus, for it to be made possible, a sheet metal bending machine is necessary. The machine’s primary function in sheet metal bending is to ensure that a workpiece forms a bend. Furthermore, the device ensures that one can get any of the desired shapes. The primary point to note is that there are different types of sheet bending machines in the market. Thus, this post aims to inform you of seven types of sheet metal bending machines.

Types of sheet metal bending machine

1. Press brake

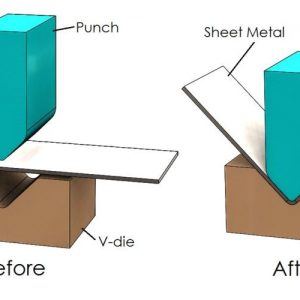

The press brake is a sheet metal bending machine that utilizes a die and a corresponding moving punch. During the bending procedure, the workpiece is placed on a die. Then force is used to move the punch into the metal. Therefore, forcing the sheet metal into the die. Additionally, the press brake machine makes U-bends, V bends, and several other shapes, depending on the die’s shape. Thus, the press brake machine is one of the most commonly used machines. Furthermore, the machine can be used for different jobs, such as angled shaping, curling, bottoming, bending, hemming, seaming, and so many others.

2. Rotary sheet bending machine

The rotary sheet bending machine, also known as the roll press sheet bending machine, is used to straighten and bend parts of; high-pressure vessels, boilers, converters, and pipes. It is best used for cold linear bending. Furthermore, sheet metal bending is attained through the processes of bending beam rotation.

3. Cornice brake

The cornice brake is a relatively simple sheet bending machine. One of its most common use is in the manufacturing of brakes. It operates by clamping a workpiece to a flat surface; then, it utilizes enough force to straighten bends or create simple creases through the bending leaf movement.

4. Hydraulic sheet bending machine

The hydraulic sheet bending machine is one of the most popular bending machines available. Its popularity is because it can be used on a number workpiece to get a variety of shapes. The machine works by using electromagnetic clamping to obtain different shapes. Some of its most crucial parts include; clamping gate, bracket, and a table.

5. Box and pan brake

The box and pan brake sheet bending machine is also referred to as a finger brake. It utilizes fingers “rows of metal” to obtain several custom bends. One of its most common use is in the manufacturing of custom-size boxes.

6. Bending roller

The bending roller sheet metal bending machine is commonly used for straightening and bending sheet metal parts and covers of the pressure vessels, boiler tanks, and converters.

7. Bar folder

The bar folder sheet metal bending machine is a simple and small bending machine. It has a single handle that makes sheet metal clamping and bending in one motion. Furthermore, the simplicity of the machine ensures that minimal skill is required for its operations.

Conclusion

The different types of sheet metal bending machines best serve various purposes. Therefore, if you wish to acquire sheet metal bending services, knowing the machine that will suit your proposed work best is essential.